The optimal manufacturing process is determined by the kind of product being manufactured and the market potential. As soon as you have decided to make a product, the first thing you should think about is choosing a production process. Most corporate owners make the blunder of considering the production process after the planning phase is complete.

Alternatively, they should consider the production process from the start of the design process, making it more cost-effective and easier to manufacture.

The following are some things to consider while figuring out how to choose a manufacturing process for your product.

Accuracy

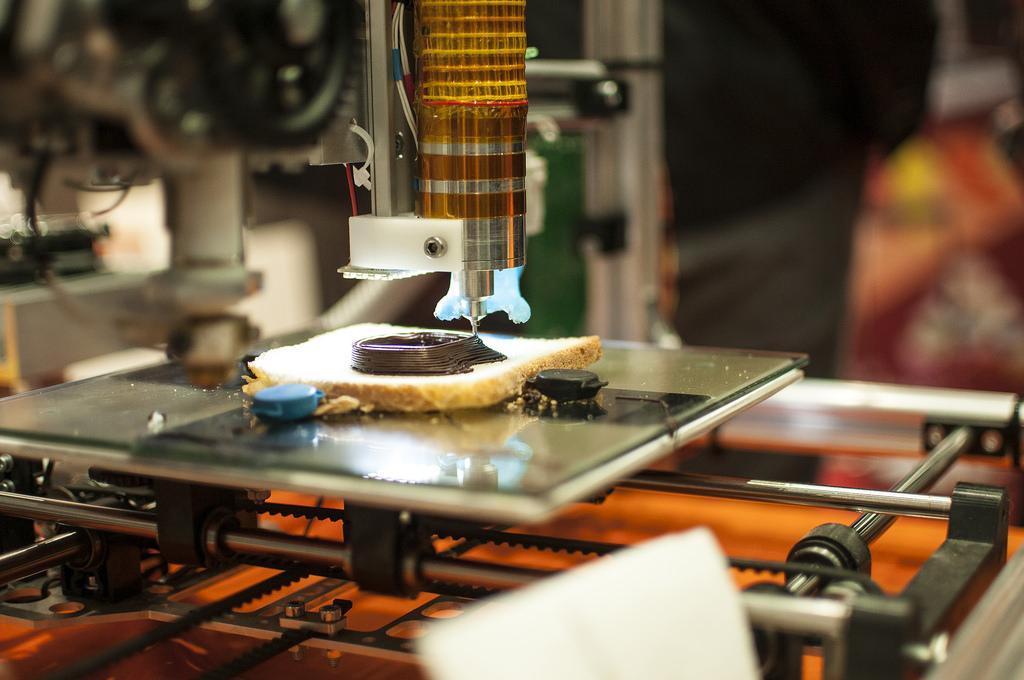

Based on the product’s shape, 3D printing accuracy is usually approximately 0.005″, regardless of technology. There are several complexities based on the alignment of the part, material, and technology continuously improving, but 0.005″ is a fair amount as a general guideline.

CNC machining may be the best option if your part requires accuracy greater than 0.005”. Alternatively, you could 3D print the model and then finish it using a CNC machine. That is additional effort, and no one would like to waste time doing something they shouldn’t have to.

Geometric Complicatedness

CNC machining is unable to create some shapes. Since CNC cutting tools make contact with the product from the top, this is the case.

It can not get to all angles of the part without turning it, which means more processing and labor time, which is a problem for most businesses. Making concealed elements and undercuts with CNC machines, for instance, is difficult.

In cases when complicated geometry is required, an additive manufacturing approach such as 3D printing may be more appropriate.

Time to market

Lead time is more critical to organizations than material suitability, geometry, or minimum feature size. So, which is faster: 3D printers or CNC machines? Whenever one of your objectives is a quick response time, 3D printing is generally the superior alternative.

Parts made with 3D printing can be made in a matter of days. These printers also remove the requirement for tooling modifications when generating a new version of a design or a new item, reducing the lead time.

While producing a larger batch, CNC machining can be a speedier procedure altogether. This is because, unlike 3D printing, CNC machined parts do not require post-processing activities.

If you make over a hundred comparable items, the faster lead time in CNC machining is significant. CNC machines can run indefinitely without monitoring once they have been configured. As a result, CNC machining can be much faster than 3D printing for similar items with over 100 pieces.

Bottom Line

3D printing and CNC machining both offer advantages that make them suited for a variety of tasks. However, there is no such thing as a universal production technology.

The final product will determine the best process for you. Ideally, those mentioned above and analyzed considerations will assist you in making the best decision possible which suits your business perfectly.